Anchor Bolt

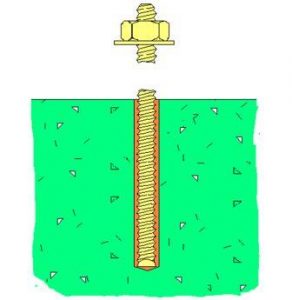

In construction projects, Anchor Bolt (Rolls Bolt) is used to install metal plates of various dimensions and thicknesses to hardened concrete, stone, bricks and so on. Get it

These pages allow the connection and welding of various metal parts to concrete structures for the implementation of dry and composite views, the implementation of the support of mechanical and electrical installations, installation of equipment and machinery. But what’s important is the choice of anchor bolt based on the type of performance, size, load capacity, and installation constraints.

Anchor Bolt is categorized in terms of type and function into two mechanical and chemical categories.

In general, the performance of the anchor bolts (grip in concrete or other materials) is carried out in four ways:

1 – Friction or Expansion

In this case, Anchar Bolt can withstand different loads after installing or planting, by creating a friction force with a base material. Often, metal deniers – these types of dentists are also known as expansions – and plastic (plate rolls) operate in this way and are easily installed.

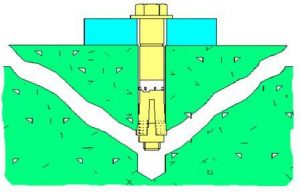

2 – Key or fastener

In this case, the anchor creates a cavity by creating a cavity or grinding the base material – in which case it is often concrete. These types of banners have a high carrying capacity and can withstand dynamic loads and be installed at short distances from the edge of the base material.

3 – Combination of Friction & Expansion

These types of banners act simultaneously in both friction and key mode. They also have a high carrying capacity and dynamic load balances.

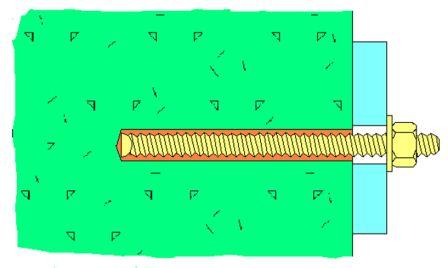

4 – Bonding

Chemical anchor bolts, also known as concrete glue or reinforcement sizing glue, create bonding strength by bonding between the rebar or rod with base materials. Advantage of using this type of anchors is the lack of use restrictions in diameter and depth of sowing.

Chemical anchor bolts

The factors that influence the choice of ancker type include:

1 – Environmental conditions

Geographic factors such as weather conditions and humidity, the presence of corrosive substances such as acids, fats, petroleum products, phosphates, sulfates, etc. at the site of the Anchor and in places such as marginal cities, refineries, Refineries, power plants, factories … are among the factors influencing Ankara’s choice. Material (steel, plastic and chemical) and coating (cold galvanizing, hot galvanizing, stainless steel, etc.) Anchor is a selection of items that are determined according to the environmental conditions.

2 – Load times

Anchor bolts can withstand various loads (between 10 and 15,000 kg), according to need, performance type, gender, load type (tensile and shear, or static and dynamic).

3 – Type of load

In general, structural loads are divided into two categories:

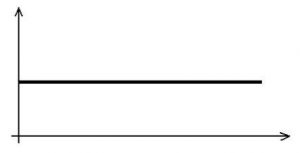

3.1 – Static Load

Static loads are fixed to the structure with constant amount and do not change over time. Dead times such as the weight of the structure, the weight of the equipment, the weight of the person and … examples of the static load. Almost all deniers handle this type of load.

3.2 – Dynamic Load

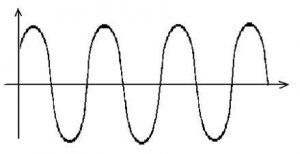

These types of loads change over time and are divided into three broad categories:

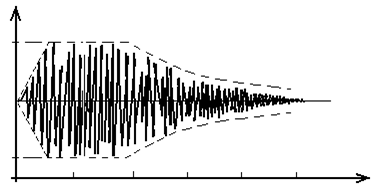

3.2.1 – Fatique

Passing people, machines, wind power, snow, all kinds of devices and equipment in operation, such as electric motors, are examples of these types of loads.

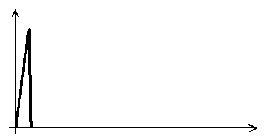

3.2.2 – Shock

This type of load occurs in very short time and due to severe collision, explosion or destruction of part of the structure.

3.2.3 – Seismic

Obviously, in order to withstand each type of dynamic load, anchor bolt must be selected.

4 – Anchor Bolt diameter and sowing depth

Based on the amount of load as well as the existing limitations, such as holes on the foundations of machinery and equipment to be installed, and other design and implementation constraints, such as the distance between the installation of anchors from the edge of the concrete and the distance between the installation of the banners, the diameter and Anchor planting depth is determined.

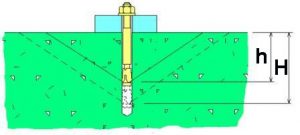

The depth of the incubator planting will be directly proportional to its bearing capacity, with the minimum and maximum consideration being given to the thickness of the base material as well as the manufacturer’s capabilities and the permission of the existing regulations.

When anchor diameter is fixed and constant due to certain restrictions, but its load is less than the load, anchor can be selected by increasing the depth of sowing. On the other hand, if the Anchor bore has been loaded more than the load, the depth of sowing can be reduced to make the best choice.

According to the above, chemical anchors are the only products that can be selected, designed and run with varying depth of sowing.

5 – Base Material

Various types of concrete, including solid, porous, light weight, cracked, aerated, etc., along with a variety of bricks, pottery (Hollow Brick ), Gypsum & Cement Board, Natural Stone (Natural Stone) and … are among the materials which are one of the decisive factors in the choice of Ankara due to various resistances.

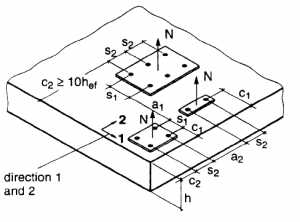

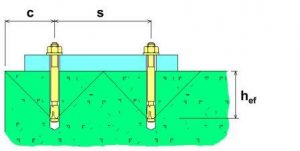

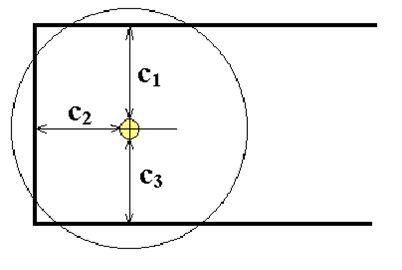

6 – Edge & Space Distance

Each type of anchor has the characteristics by which it must be installed at a specified distance from the free edge of the concrete, also at a specified distance.

7 – Runtime requirements

Generally, anchors are installed in two ways:

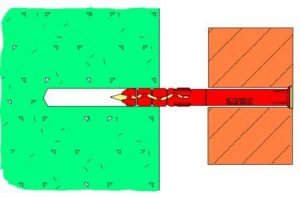

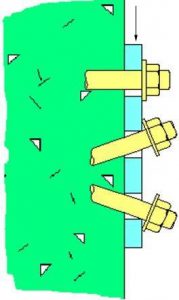

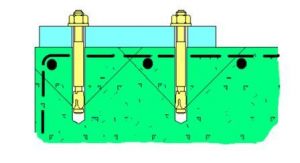

7 .1 – Through Fastening

In the first method, anchor bolt and metal plate are mounted simultaneously

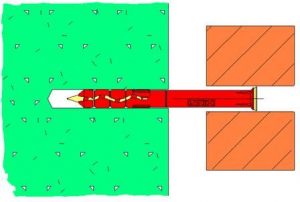

7 . 2 – Pre Setting

In this method, anchor Bolt is first planted, and then the metal plate, rod, armature, equipment and … are installed at the right time.

Anchor Failure :

1 – Pull Out

In this case, the anchor bolt is removed from the hole without damaging the anchor bolt, metal plate and concrete.

Failure to observe the Ancker installation specifications is the most important reason for this failure

2 – Pull over

The inappropriateness of the load loaded with the thickness of the metal plate causes this failure. In this case, the metal plate is damaged

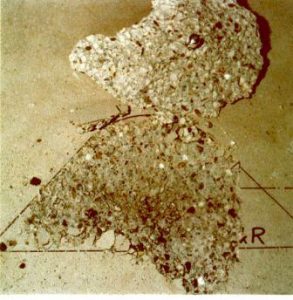

3 – Concrete Breakage

When anchor is installed in concrete, tensions are applied in a concrete cone in a conical space. If the concrete can not withstand this tension, concrete cone failure occurs.

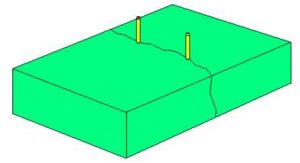

4 – Cracking of Base Material

This failure occurs when the minimum distance between two Anchors for each other or at least the distance between the Anchor installation and the concrete edge is not met.

5 –Steel Breakage

In this case, the load volume is greater than the Anchor bolt tensile strength and the Anchor bolt is thus cut off

Effective factors in the design of Anchor Bolt

In many cases, due to the circumstances and the importance of installation, the choice of the appropriate Anchor should be made by designing and based on some bases and related theories. Some of the factors that affect Anchor bolt design include:

1- Directional load

All loads of any kind and nature can be converted into two types of loads:

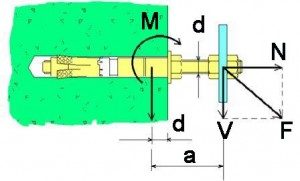

1.1 – Tensile Load , N

1.2 – Shear Load , V

For this reason, various types of anchors are known for tensile and shear bearing capacity, and for the design of anchor, the amount of these loads should be specified.

2 – Type of load

The static or dynamic design of the load must be determined

3 – The load on the structure

All the loads that enter the structure (and not the anchor) should be taken into account in the design of the anchor. These loads can include the weight of structural members and equipment that are permanently installed (dead loads) or loads of wind, snow, earthquakes, or equipment and machinery in operation.

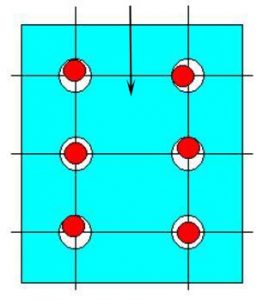

4 – The load arrived at Anchor Bolt(Roll Bolt)

Due to the existence of some limitations, such as improper installation of anchors, all of them can not withstand evenly loaded loads. As shown in the illustrations above, only three buckets tolerate the inclined shear load. To prevent this problem, the gap between the anchor and the hole between the metal plate can be filled in with methods such as the use of special washers (Dynamic Set).

Obviously, the use or non-use of this method should be specified in the design.

5 – Basic materials

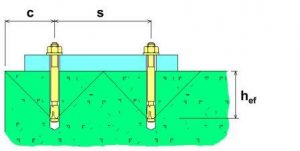

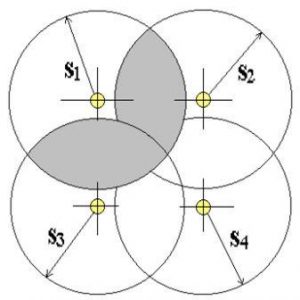

6 – Anchor bolts distance from each other and distance from the edge of the base material

As long as the stress cones formed by each anchor do not interfere with each other or are distanced from the edge of the base material, the anchor bearings will not be reduced, but if these distances are less, then it is necessary to apply the reducing coefficients on the anchor bearings To make.

Obviously, these distances can not be reduced to a certain extent

7 – Planting depth

Changes in sowing depth can cause the size of the stress cone to be affected, which will affect the design.

8 – Concrete reinforcing rails

The presence of concrete reinforcing bars can help reduce the effect of tensile cones

9 – Cracked concrete

When concrete as a base material is pulled out by force, the cracks are created on it that are often not visible to the eye and do not exceed the size of 0.3 mm.

When anchors are installed in these areas, and when the loads are of a dynamical type, the presence of these cracks decreases the ancher engagement with concrete due to the crack opening and closure, and it eliminates the integrity of the formed cone cone Gets As a result, Anchor will be between 30 and 35, which will affect Anchor design.

10 – Ancher bolt behavior on fire

When the anchors are exposed to an outbreak of fire or explosion, they will be reduced by time. Therefore, there is information about the behavior and the amount of reduction in their bearing in direct impact design.

Design regulations:

Anchor design is based on building codes. Before selecting a regulation, it is necessary to specify the design purpose, which is divided into two parts

Installation of metal plate and planting of rebar

ICBO, ACI, SOCOTEC, Dibt, ETA are among the most prominent ETA (Europe) and ACI (US) regulations.

ETAG : Europian Technical Approval Guidline

ETAG 001 Annex C

Mechanical

Standard Layout

Standard Embedment Depth

ETAG 020

Plastic Anchors

EOTA TR 029

Design of Bonded Anchors

ETAG Fire : Based on EOTA TR 020

Evaluation of Anchorages in Concrete Resistance to Fire

ICC : Design Method Using the Provision of ACI 318-05 and ICC-ES AC 193 and AC 308

Chemical Anchor bolt or Concrete Glue :

The lack of proper implementation of the rearmament, the modification of the structural drawings, the insertion of new components, and the resilience of the concrete and the continuation of concrete operations in cases where the installation of rebar is forgotten or not foreseen, is one of the common issues in the implementation of concrete structures, and one The best and least costly solutions to the disadvantages and repair of the above are the planting of rebar with chemical anchors or concrete adhesives. In the same way, it is possible to install metal plates on the concrete surface by planting the threaded fittings.

The planting operations of the rebar consist of drilling with a specific diameter and precision in concrete, injection of chemicals in the hole and rebar processing. Due to the sensitivity and importance of the thread, the company carries out all the necessary tasks including design with specialized software, advice and complete report The technical and implementation of planting fully takes place.

Anchor Bolt Applications:

Installation of partitions, false ceilings, sanitary ware, hospital equipment, concrete prefabricated panels, building metal facades, elevator and escalator lifts, metal scaffolding hinges, supports and holders of plumbing and channeling systems, equipment and machinery Machinery, railway and underground railways, overhead cranes, port equipment, aircraft hangars, electric and telecommunication towers, etc. are examples of the use of this product.

Announcements are available in reputable brands such as HILTI, Fischer, Spit as well as other brands.

The company, with its specialty and experience in the design of Ankara Bolt types, is using advanced and specialized software and experienced engineering team to provide technical advice and engineering services and calculations to select the right products for free. Construction and industrial.